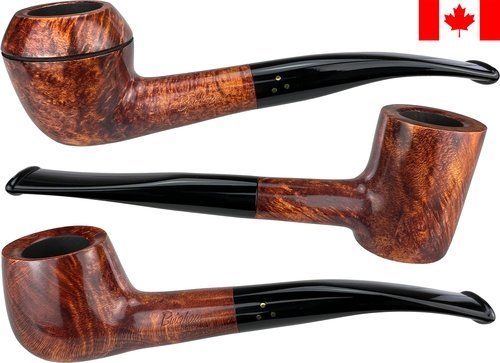

Brigham Pipes: Tradition and Innovation Since 1906

In 1906, Roy Brigham established a small pipe repair workshop in Toronto. Having trained under an Austrian pipe maker, he was well-versed in the intricacies of craftsmanship. By 1918, his company had grown to include five additional employees—a clear testament to its success. During his work, Brigham frequently identified weaknesses in existing pipes and often encountered smokers’ complaints about tongue bite, a problem that would continue to occupy his attention.

Roy Brigham and the Pipe Filter Revolution

Over time, the company began manufacturing its own pipes, renowned for their improved designs and superior quality. In 1938, Roy's son Herb joined the family business, and together they experimented with ways to reduce tongue bite. They discovered that specialized pipe filters could significantly mitigate this issue.

The filters were initially made from a variety of materials, both locally sourced and imported. However, only filters made from bamboo and the so-called “Rock Maple” (sugar maple) met their high standards. Since bamboo was expensive and hard to source, Brigham opted for the locally abundant maple wood.

Small Masterpieces Made of Maple: Brigham Rock Maple Filters

The Brigham Rock Maple Distillators Filters exemplify innovative craftsmanship. These filters consist of a maple wood tube with an aluminum tip, measuring approximately 9 cm in length. The filter is positioned within both the shank and the mouthpiece, offering excellent filtration. It not only reduces moisture in the smoke but also provides a pleasantly mild smoking experience.

Unlike conventional filter systems, Brigham recommends reusing these filters. They can even be rinsed with water and reused once dried. However, their filtering performance diminishes over time, and replacement is recommended after 20 to 30 uses.

Eco-Friendly Alternative

Made from sugar maple, these filters are not disposable. Their reusability makes them an eco-friendly alternative to conventional systems. Compared to activated charcoal or meerschaum, they eliminate the need for fossil materials and resource-intensive mining processes. The raw material grows locally, right in Toronto.

Brigham Pipes: Canadian Craftsmanship with History

The golden era of Brigham Pipes was the 1960s, when over 40 employees were engaged in production. However, over time, the rising shortage of skilled labor, combined with an aging workforce, led to the relocation of much of the production to the European Union starting in 2001. Today, Brigham continues to focus on quality and innovation, even though production is no longer exclusively based in Canada.